Pull Down Chuck

The workpiece can be clamped radially and pulled back axially at the same time, ensuring that the workpiece is tightly pressed against the reference surface without floating upwards.

Can be used in conjunction with air tightness testing to confirm axial positioning.

Cylindrical sliding structure ensures high clamping precision and durability. Suitable for heavy cutting and machining where precise axial length is required.

The chuck is divided into two types: external clamping and internal support, and offers a variety of options including two-jaw, three-jaw, four-jaw, and six-jaw versions.

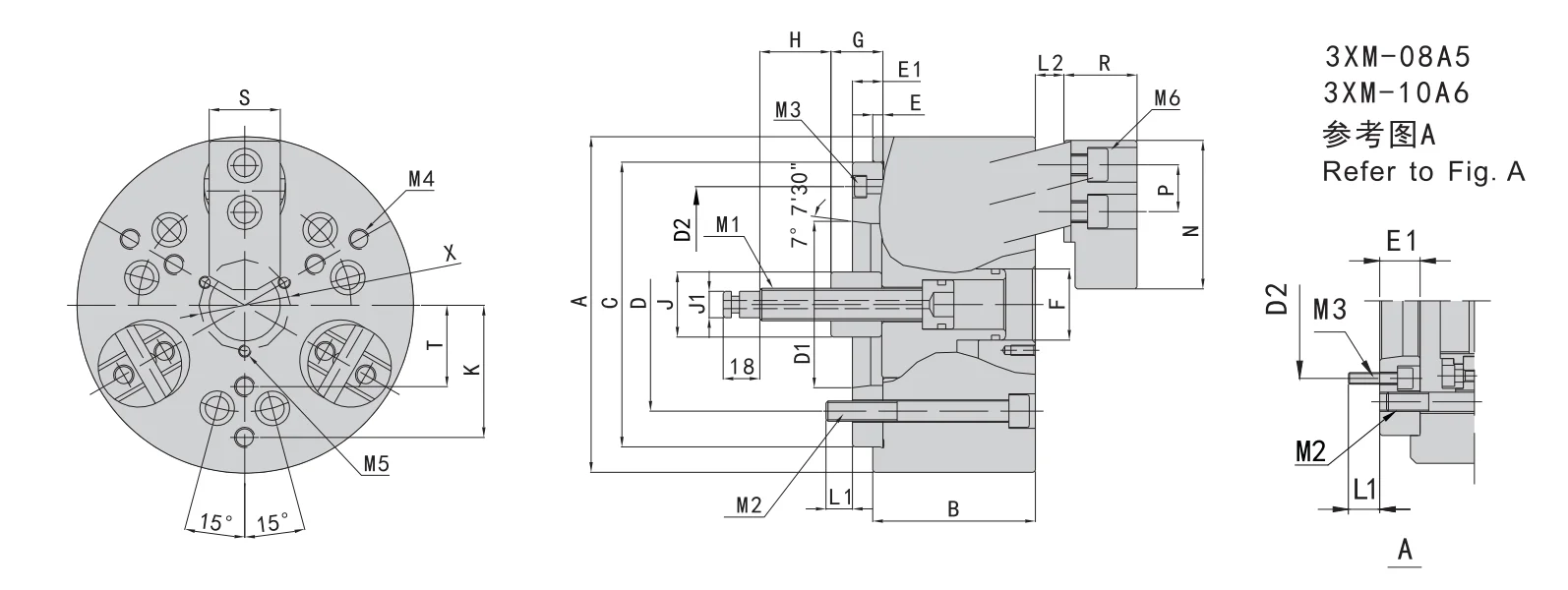

3-Jaw Pull Down Chuck

| Model | Flange | A | B | C (H6) | D | D1 | D2 | E | E1 | F | G | H | J | J1 | K | L1 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | min | ||||||||||||||||

| 3PB-06 | A5 | 165 | 85 | 140 | 104.8 | 82.56 | 116 | 5 | 15 | 35 | 30 | 15 | 35 | 32 | 13 | 55 | 13 |

| 3PB-08 | A5 | 210 | 100 | 170 | 133.4 | 104.8 | 23 | 45 | 27 | 7 | 38 | 37 | 16 | 75 | 17 | ||

| A6 | 106.38 | 150 | 17 | ||||||||||||||

| 3PB-10 | A6 | 254 | 110 | 220 | 171.4 | 133.4 | 25 | 55 | 31 | 11 | 41 | 48 | 20 | 85 | 19 | ||

| A8 | 139.72 | 190 | 18 | ||||||||||||||

| Model | Flage | Piunger Stroke(mm) | Jaw Stroke(Dia.)mm | MaxPull force KN(kgf) | Max.Gripping forceKN(kgf) | Max Speed r/min | Clamping range(mm) | Moment of inertialkg.m2 | Weight kg | Maching Cylinder | Max.preessure Mpa(kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3PB-06 | A5 | 15 | 7.8 | 9(910) | 25(2550) | 3500 | 22-165 | 0.05 | 16.8 | 75Q | 2.5(25) |

| 3PB-08 | A5 | 20 | 10.3 | 16(1630) | 45(4590) | 3000 | 28-210 | 0.14 | 28.9 | 100Q | 2.2(22) |

| A6 | 27.1 | ||||||||||

| 3PB-10 | A6 | 20 | 10.3 | 21(2140) | 60(6120) | 2500 | 35-254 | 0.36 | 53.5 | 125Q | 1.9(19) |

| A8 | 51.5 |

We also offer 2-jaw (2PB), 4-jaw (4PB), and 6-jaw (6PB) pull-back chucks. For more details, please consult our customer service.